Where once silver was mined, now jeans are

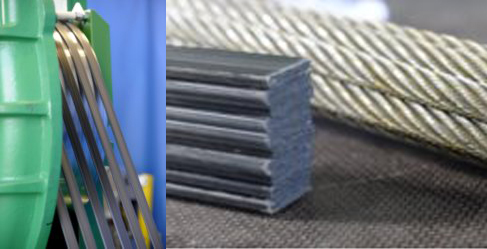

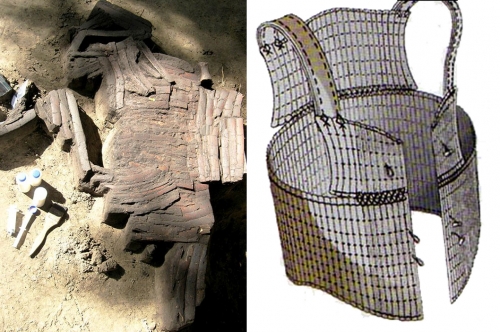

To me, this sounds like the story line from a children’s book, but no, this is something that really happens. Michael Allen Harris and his father-in-law hunt for jeans from the 1800’s in abandoned silver mines. Recently they found a pair of Levi’s from 1873, the year they were first manufactured, that could still be worn. It makes me think of the image on a Levi’s label of two horses trying and failing to pull apart a pair of Levi’s jeans to demonstrate their robustness. They were obviously made to last.

Website link: I mine for 100 year old jeans, The Guardian, 25th September 2015

Video link: Levi Strauss – preserving the past