WE COLLABORATE: as a team of engineers, designers, prototypers and seamstresses, we value close collaboration with clients and external subject-matter experts. We pride ourselves on asking questions, and regularly host creative sessions with our clients to fully understand their vision, help drive new design ideas and provide fresh direction.

WE’RE STRATEGIC: We conduct intelligent research into products, processes and materials to deconstruct and simplify ideas into solutions that work. While no two projects are the same, our design process remains consistent: we listen, research, create, test, and deliver.

WE’RE TECHNICAL: Our knowledge of conventional and technical materials is broad and always expanding, enabling us to offer expert guidance on materials’ capabilities, benefits and limits. As a technically-minded group of people our practical dexterity shines through in our detailed prototypes and finished products.

WE’RE USER LED: The users are at the core of all of Thread’s projects, and the use-experience is key in evaluating the strength of a product. Our user-led approach to design enables us to construct products that solve problems and create an impact for their users.

Design

We work closely with our clients to realise their aims. Some know exactly what they want their product to be like, and others come to us with a problem to solve. Collaborative sessions are a great way to find solutions, generate ideas and drive innovation:

- Concept generation creative sessions

- Workshops with clients and expert teams

- Making days to create and test concepts quickly

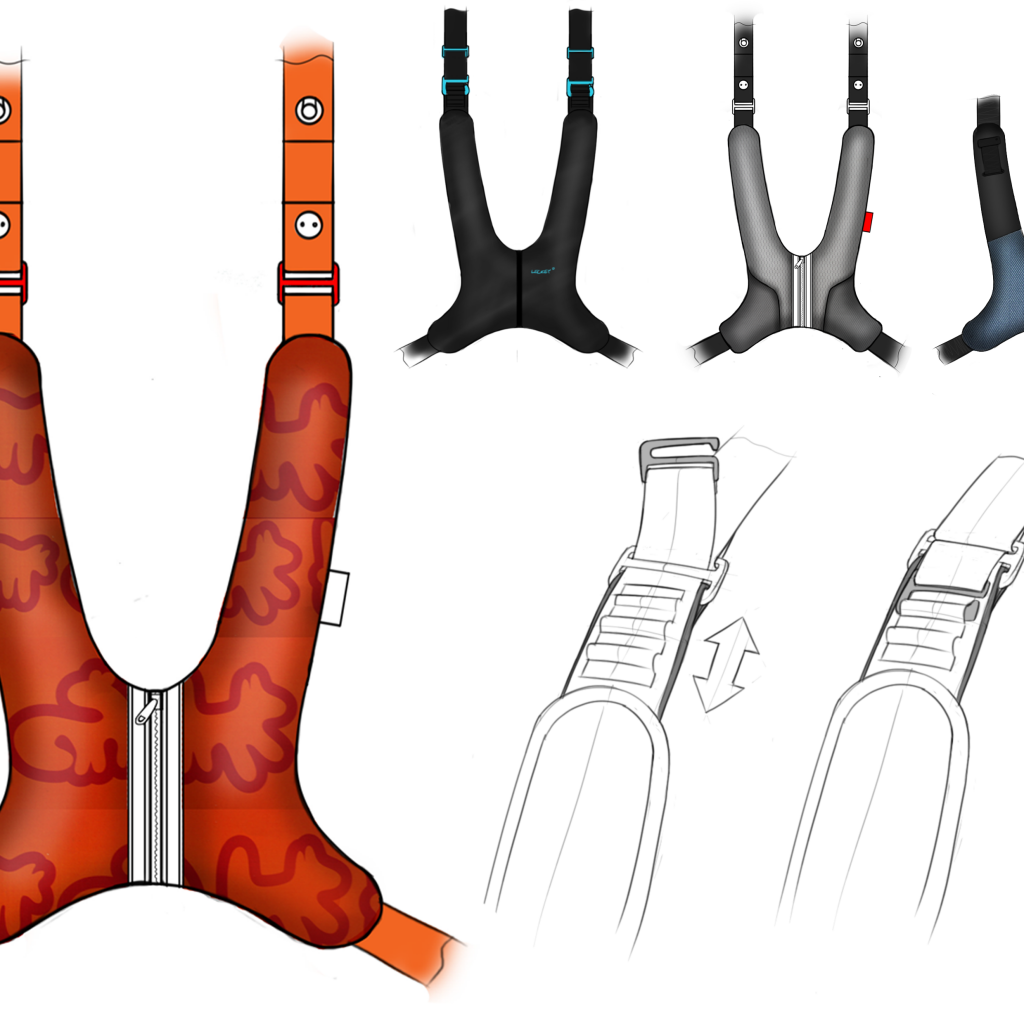

Through 2D sketching, 3D CAD, sketch prototyping and iterative prototyping, we develop concepts from ideas into fully featured working products that fulfil complex requirements. We explore multiple options and test them out so that the end result is the best it can be.

Engineering

We develop and incorporate mechanical and functional features such as mechanisms and moulded fixtures into products we design, and can develop moulded components, mechanisms and internal structural elements.

We build test rigs to evaluate and inform our teams and clients about prototypes and concepts.

Materials

We support our clients in identifying material properties that will be suited to the application, environmental requirements, biocompatibility, price, finish, comfort, physical properties. We are able to navigate the endless variations and subtleties of textiles to create products that work.

Materials, fixtures and fittings are sourced globally. Our materials library is continually growing and contains materials from cotton canvas to highly technical textiles. We are continually looking for new fabrics to fulfil our clients’ needs.

Prototyping

Making is at the heart of our approach to designing. We prototype to explore, develop, test, communicate and sell ideas, concepts and products. This important with all design projects, and is especially important with textiles.

Our prototyping studio is equipped with industrial sewing machines, a laser cutter, bonding presses, cutting presses, seam sealing machines, and rolls and rolls of fabrics with which we can make almost anything out of textiles.

In our prototyping workshop and lab, we 3d print and assemble mechanical parts of products, test rigs and jigs.

Creatively prototypes are used to explore and build on ideas, we use anything that’s to hand to communicate and test. We call these kinds of prototypes lash-ups or if we’re making a garment, we might call it a toile.

In development, prototypes are important milestones where we can test our ideas. A stake in the ground where we demonstrate our thinking, and learn about our designs. We test their performance, we use them to demonstrate progress, and you can use them to show stakeholders and get buy in.

Iteratively developing a design, we improve, and hone a concept into a product that is ready to manufacture.

We use samples and prototypes to communication the construction, and the quality required to manufacturers. This, along with a specification is how we ensure the most efficient transition a manufactured product.

Pilot Line

Pilot production at Thread Design has been instrumental in verification and user testing our medical and consumer clients’ concepts and products.

We build prototypes and products we have designed in the 10s to 100s to be used in Research and Development of products, user trials, medical device validation and verification trials and clinical trials.

Medical pilot production – Quality and record keeping is of paramount importance. We generate and maintain documentation for all aspects of quality of the finished articles, including goods-in, assembly, training, final inspection, traceability and delivery in line with our clients’ medical regulatory teams’ requirements.

Manufacture Support

Manufacture lead times often get extended by toing and froing with the factory. This is why we take an engineering approach to technical packs. Patterns, samples and detailed specifications eliminate ambiguity in the handover from designer to manufacturer, minimising errors that can arise through misinterpretation.