Looking forward, looking Eastward…

During lockdown the Thread team was fragmented with most of us at home (and communicating digitally) and only physical prototyping tasks taking place at the studio. Now we’re all (except one) back in the studio we can get back to our normal (but precious) face-to-face process of collaboration.

All the physical upheaval and emotional strain of the last 6 months has brought the importance of the overall health of Thread into sharp focus. I was looking for a structure to guide me in this and began researching the concept of Gross National Happiness (GNH) which is used in Bhutan as an alternative measure of a country to Gross Domestic Produce (GDP). I’ve been reading (and getting much inspiration from) “Proposed GNH of Business” by Tshoki Zangmo, Karma Wangdi and Jigme Phuntsho.

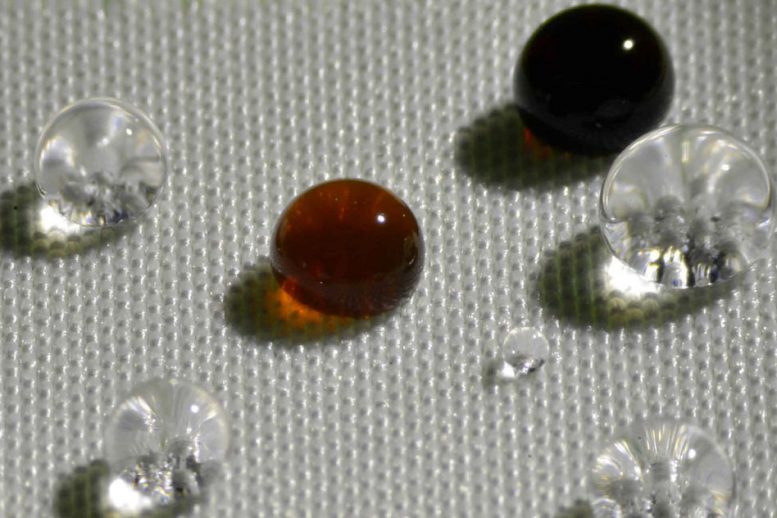

How can baby product design save parents time? Reduced mess = less tidying.

How can baby product design save parents time? Reduced mess = less tidying.