Making is at the heart of all projects at Thread. We prototype to explore, develop, test, communicate and sell ideas, concepts and products. This important with all design projects, and is especially important with textiles.

Our prototyping studio is well equipped with industrial sewing machines, bonding presses, cutting presses, seam sealing machines, and rolls and rolls of fabrics with which we can make almost anything out of textiles.

In our prototyping workshop and lab, we 3d print assemble mechanical parts of products, test rigs and jigs.

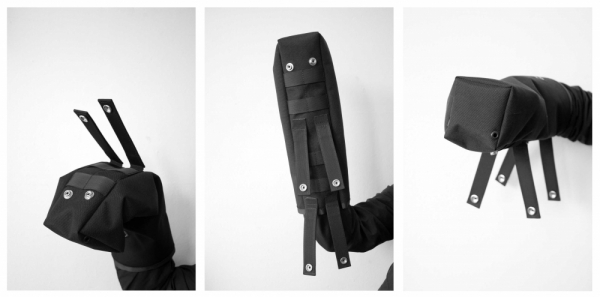

Creatively prototypes are used to explore and build on ideas, we use anything that’s to hand to communicate and test. We call these kinds of prototypes lash-ups or if we’re making a garment, we might call it a toile.

In development, prototypes are important milestones where we can test our ideas. A stake in the ground where we demonstrate our thinking, and learn about our designs. We test their performance, we use them to demonstrate progress, and you can use them to show stakeholders and get buy in.

Iteratively developing a design, we improve, and hone a concept into a product that is ready to manufacture.

We use samples and prototypes to communication the construction, and the quality required to manufacturers. This, along with a specification is how we ensure the most efficient transition a manufactured product.

Get in touch if you need a prototype made, or want to know more: