Visual samples

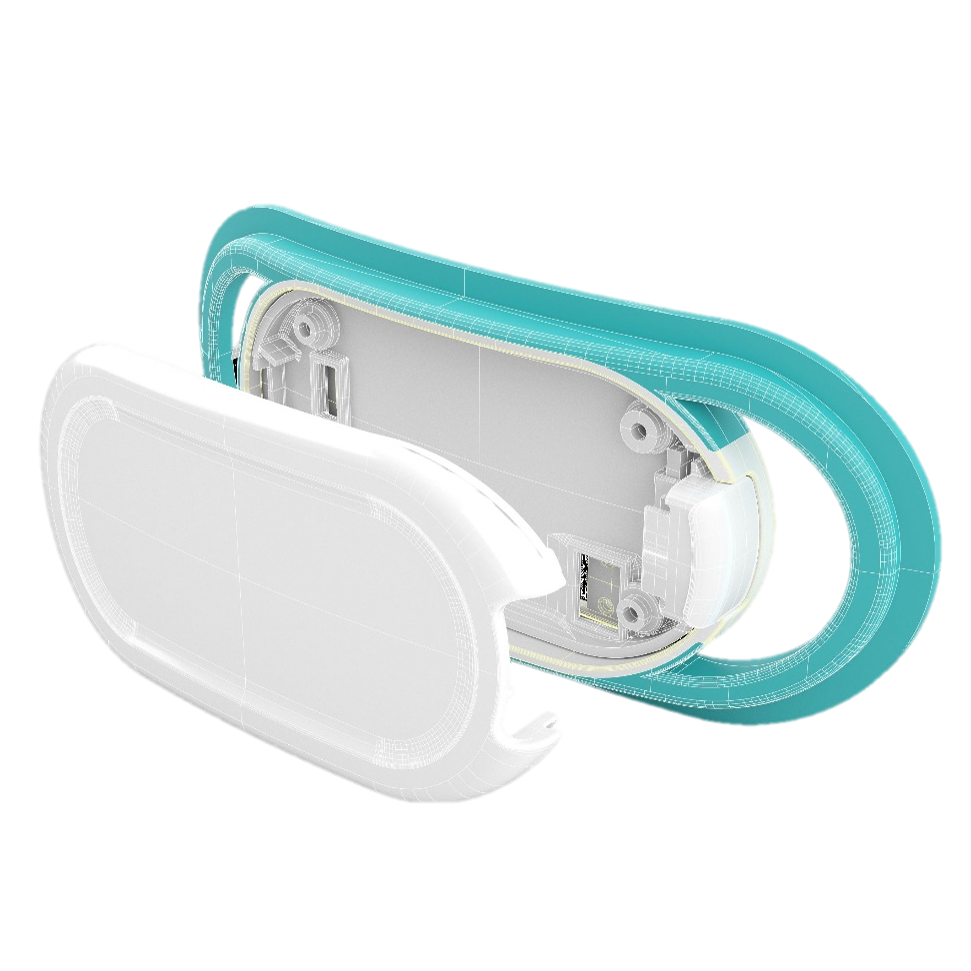

We produce beautifully finished textile based prototypes of concepts for our clients to use in many different ways.

Market research, user research, for demonstrations, photo and video work.

We work hard to create prototypes that work right and look great. To get the right feel, we make these prototypes with representative materials. We work to bring the appearance as close as possible to the intended product. We do this by matching colours where possible, and applying logos and branding.

As a result, our clients can use these prototypes to get meaningful feedback from customers, to sell projects both internally and externally and generate a buzz around their projects.

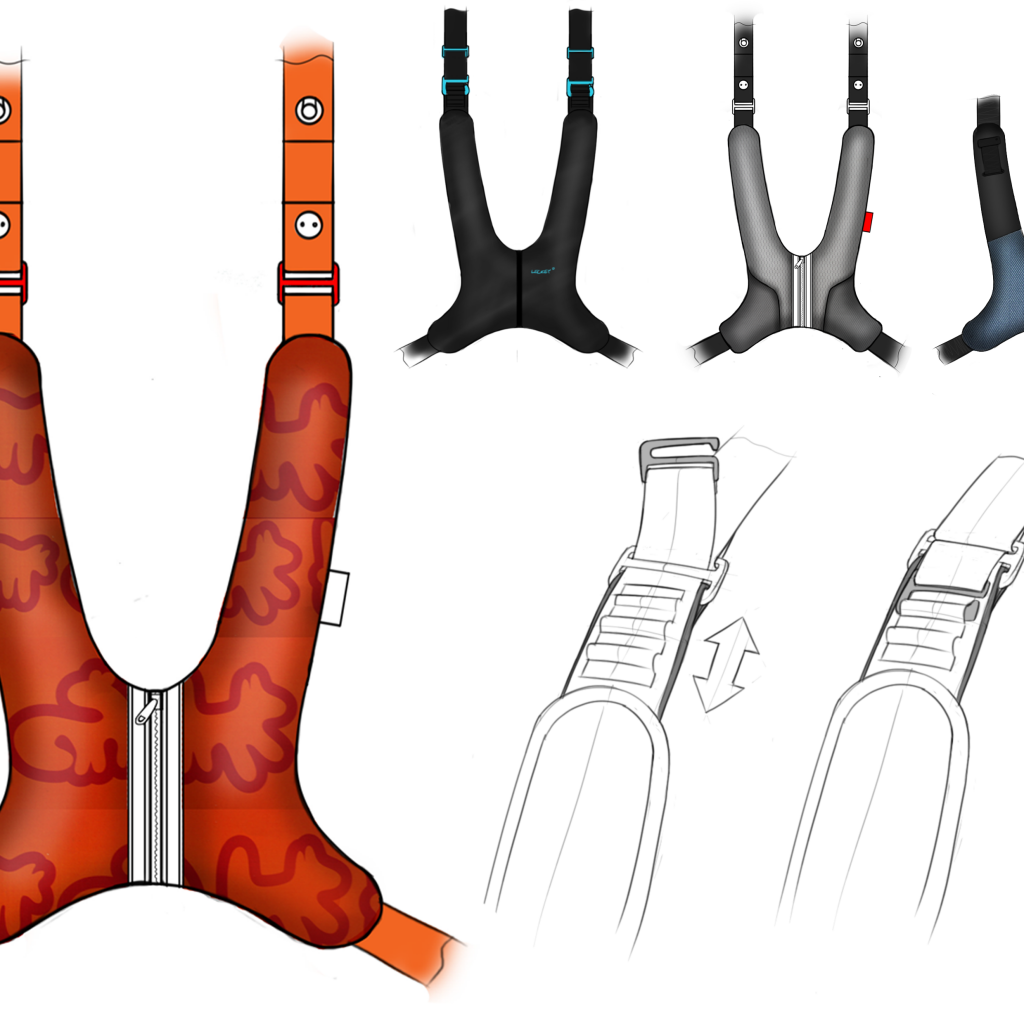

Manufacture

Golden samples are preproduction samples that represent the construction, look and feel of the end product as closely as possible to eliminate ambiguity. A golden sample is made (along with technical specifications) to guide manufacturer in the intended look and feel construction and quality of the product. This is especially required in the case of complex products because a finished article communicates so much more than a set of drawings. Manufacturers use this information for their sampling prior to production.

With a well made golden sample in yours and your manufacturer’s hand, you’ll be able to translate your concept into a great product more easily.