Old skills, new product

As a child Dr Franz Freudenthal visited indigenous communities in the mountains of Bolivia with his doctor grandmother. On these trips she would quote a snippet of Rudyard Kipling “Something hidden. Go and find it. Go and look behind the mountains. Something lost behind the mountains. Lost and waiting for you. Go!” It seems unlikely he could have predicted the importance of the words or the trips. As a paediatric cardiologist he went on to utilise the weaving skills of the indigenous Aymara women to develop an implant to close ‘holes in the heart’.

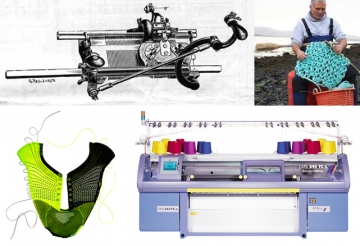

The device is woven by Aymara women in a clean room environment from a single strand of Nitinol, a nickel-titanium alloy that is superelastic and has shape memory. These material properties allow the woven implant to be compressed inserted into the body via a catheter in the groin and only expanded to its ‘top hat’ form when it is correctly positioned in the heart.

“The most important thing is that we try to get really really simple solutions for complex problems” Dr Franz Freudenthal, Paediatric Cardiologist

Website link: “A new way to heal hearts without surgery”, TED